0

সম্পূর্ণ খামার সরঞ্জামের তালিকা গ্রহণ করুন

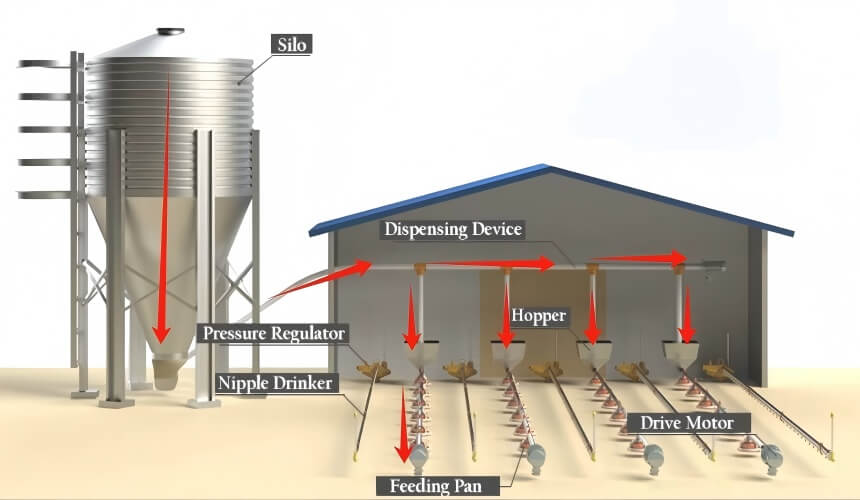

স্বয়ংক্রিয় পোল্ট্রি সরঞ্জাম: খাঁচা, খাবার, পানি, ডিম সংগ্রহ, মল অপসারণ ও জলবায়ু নিয়ন্ত্রণের জন্য এক ছাদের নীচে, মডুলার ডিজাইন ও আপগ্রেড-যোগ্য

১. সম্পূর্ণ টার্নকি ব্রয়লার পালনের সিস্টেম

একক, একীভূত সলিউশনের মাধ্যমে এন্ড-টু-এন্ড স্বয়ংক্রিয়তা আনলক করুন:

আবহাওয়া-নিয়ন্ত্রিত ব্রুডার

জন্মের পর থেকেই ইউকোলজিক টেম্পারেচার ও আর্দ্রতা নিয়ন্ত্রণ নিশ্চিত করে সুস্থ ছানাদের জন্য।

মাল্টি-টিয়ার খাঁচা মডিউল

৩–৪ স্তরের ভার্টিক্যাল ফার্মিং, স্বয়ংক্রিয় ফিডিং, পানির ব্যবস্থা, ম্যানিওর রিমুভাল, ও ভেন্টিলেশন সহ।

সেন্সর-চালিত পরিবেশ নিয়ন্ত্রণ

রিয়েল-টাইম মনিটরিং via PLCs: তাপমাত্রা, বায়ু প্রবাহ, এবং গ্যাস মান সবই অপরাজেয় ব্যালেন্সে।

নিরবিচ্ছিন্ন ম্যানিওর ব্যবস্থাপনা

বেল্ট কনভেয়র দ্রুত বর্জ্য সরিয়ে নিয়ে যায়, হাইজিন উন্নত করে এবং রোগ প্রতিরোধ বাড়ায়।

স্বয়ংক্রিয় ডিম হ্যান্ডলিং

(যেখানে প্রযোজ্য) কোমল কনভেয়র ডিম সংগ্রহ করে সরাসরি গ্রেডিং স্টেশনে পৌঁছে দেয়।

উপকারিতা: উচ্চতর থ্রুপুট, অবিচ্ছিন্ন গুণগত মান, ও কর্মী খরচে নাটকীয় সাশ্রয়।

২. স্বয়ংক্রিয়তার বিনিয়োগ ও মূল্য নির্ধারণ

স্বচ্ছ কস্ট টিয়ার–এর মাধ্যমে আপনার ROI পরিকল্পনা করুন:

| ফার্ম আকার | পাখির সংখ্যা | বিনিয়োগের পরিধি (USD) |

|---|---|---|

| ছোট-পরিসর | 2,000–10,000 | $100,000–$250,000 |

| মধ্য-পরিসর | 10,000–50,000 | $250,000–$600,000 |

| বৃহৎ কমপ্লেক্স | 50,000+ | $600,000–$1,000,000+ |

মূল্য নির্ধারণের প্রধান চালিকা শক্তি: কেজ টিয়ার, ক্লাইমেট কন্ট্রোল সিস্টেম, রোবোটিক ডিম-হ্যান্ডলিং, এবং স্টিল-স্ট্রাকচার ইন্টিগ্রেশন।

৩. সঠিক নির্মাতা নির্বাচন

সরবরাহকারী নির্ধারণের জন্য এই টপ ট্রেইট–গুলো খুঁজুন:

গবেষণা ও উদ্ভাবন

– উন্নত IoT প্ল্যাটফর্ম, প্রেডিক্টিভ ডেটা অ্যানালিটিক্স, এবং স্মার্ট সেন্সর।গঠনগত মান

– ক্ষয়-প্রতিরোধী মেটেরিয়াল, প্রিসিশন মেশিনিং, এবং মডুলার ডিজাইন।পর-বিক্রয় সেবা

– অন-সাইট কমিশনিং, অপারেটর প্রশিক্ষণ, রিমোট ডায়াগনস্টিক্স, এবং দ্রুত স্পেয়ার-পার্টস ডেলিভারি।

কেন Yunhua?

আমাদের প্রতিযোগিতামূলক মূল্য, ISO-সার্টিফাইড প্রোডাকশন, এবং ৫০+ দেশে প্রমাণিত গ্লোবাল ট্র্যাক রেকর্ড–এর সংমিশ্রণ আপনাকে সেরা নিশ্চিত করে।

৪. সরঞ্জামের বৈচিত্র্য ও বাজার চাহিদা

আজকের ফার্মগুলো যে কোন স্তরের অটোমেশন–ই বেছে নিতে পারে:

বেসিক খাঁচা লাইন

ম্যানুয়াল ফিডিং + সেমি-অটোমেটিক পানির ব্যবস্থামধ্য-স্তরের অটোমেশন

ইলেকট্রনিক ডিম গ্রেডিং + ক্লাইমেট-নিয়ন্ত্রিত ব্রুডারসম্পূর্ণ স্বয়ংক্রিয় ফ্যাক্টরি

ইনক্যুবে�শন, ফিডিং, গ্রেডিং, প্যাকিং, এবং টার্নকি স্টিল-স্ট্রাকচার বিল্ডিং

বাজার চালিকা শক্তি: বর্ধিত শ্রম খরচ, কঠোর বায়োসিকিউরিটি নিয়ম, এবং স্কেলেবল, মডুলার প্ল্যাটফর্ম–এর প্রয়োজন।

৫. সুবিধা ও বাস্তব চ্যালেঞ্জ

সুবিধা

৬০% পর্যন্ত শ্রম হ্রাস

৩০%+ উৎপাদনশীলতা বৃদ্ধি

স্বয়ংক্রিয় বর্জ্য ব্যবস্থাপনা–এর মাধ্যমে উন্নত সংগৃহীত স্বাস্থ্য

কন্টিনিউয়াস পরিবেশ নিয়ন্ত্রণ

চ্যালেঞ্জ

উচ্চ প্রারম্ভিক মূলধন

প্রশিক্ষিত টেকনিক্যাল স্টাফের প্রয়োজন

স্থানীয় সার্ভিস অবকাঠামোর পার্থক্য

প্রো টিপ: প্রমাণিত সিস্টেম ডিজাইন, সম্পূর্ণ প্রশিক্ষণ, এবং লোকাল সার্ভিস এগ্রিমেন্ট–এর মাধ্যমে ঝুঁকি স্বাভাবিক করুন।

৬. উদীয়মান প্রবণতা

এআই ও আইওটি একীকরণ: রিয়েল-টাইম স্বাস্থ্য মনিটরিং, প্রেডিক্টিভ মেইনটেন্যান্স, স্বয়ংক্রিয় ডিসিশন-মেকিং।

সবুজ কৃষি: সোলার-পাওয়ারড ভেন্টিলেশন, ফিড-সেভিং ট্রাফ, বর্জ্য-অনুবর্তক সার্কুলার লুপ।

মডুলার সম্প্রসারণ: নির্দিষ্ট ব্রীড ও দ্রুত স্কেলিং–এর জন্য কাস্টম মডিউল।

ওয়ান-স্টপ প্ল্যাটফর্ম: একক পার্টনার সলিউশন—ফার্ম ডিজাইন থেকে ডিজিটাল ম্যানেজমেন্ট পর্যন্ত।

উপসংহার ও আহ্বান

আধুনিক, বুদ্ধিমান পোল্ট্রি সরঞ্জাম মুরগি চাষে ভূমি ব্যবহারে সর্বোচ্চ, উৎপাদন বৃদ্ধি, এবং পশু কল্যাণ নিশ্চিত করছে। আপনি ১০,০০০ পাখি–র স্টার্টার ফার্ম বা ১০ লক্ষ পাখি–র কমপ্লেক্স পরিকল্পনা করুন—সঠিক অটোমেশন লেভেলই দেবে স্থিতিশীল লাভ।

আপনার অপারেশন রূপান্তর করতে প্রস্তুত?

আজই আমাদের সাথে ফ্রি পরামর্শ, কাস্টম ফার্ম ডিজাইন, এবং টার্নকি বাস্তবায়নের জন্য যোগাযোগ করুন!

১. সম্পূর্ণ টার্নকি ব্রয়লার পালনের সিস্টেম একক, একীভূত সলিউশনের মাধ্যমে এন্ড-টু-এন্ড স্বয়ংক্রিয়তা আনলক করুন:

১. সম্পূর্ণ টার্নকি ব্রয়লার পালনের সিস্টেম

একক, একীভূত সলিউশনের মাধ্যমে এন্ড-টু-এন্ড স্বয়ংক্রিয়তা আনলক করুন:

আবহাওয়া-নিয়ন্ত্রিত ব্রুডার

জন্মের পর থেকেই ইউকোলজিক টেম্পারেচার ও আর্দ্রতা নিয়ন্ত্রণ নিশ্চিত করে সুস্থ ছানাদের জন্য।

মাল্টি-টিয়ার খাঁচা মডিউল

৩–৪ স্তরের ভার্টিক্যাল ফার্মিং, স্বয়ংক্রিয় ফিডিং, পানির ব্যবস্থা, ম্যানিওর রিমুভাল, ও ভেন্টিলেশন সহ।

সেন্সর-চালিত পরিবেশ নিয়ন্ত্রণ

রিয়েল-টাইম মনিটরিং via PLCs: তাপমাত্রা, বায়ু প্রবাহ, এবং গ্যাস মান সবই অপরাজেয় ব্যালেন্সে।

নিরবিচ্ছিন্ন ম্যানিওর ব্যবস্থাপনা

বেল্ট কনভেয়র দ্রুত বর্জ্য সরিয়ে নিয়ে যায়, হাইজিন উন্নত করে এবং রোগ প্রতিরোধ বাড়ায়।

স্বয়ংক্রিয় ডিম হ্যান্ডলিং

(যেখানে প্রযোজ্য) কোমল কনভেয়র ডিম সংগ্রহ করে সরাসরি গ্রেডিং স্টেশনে পৌঁছে দেয়।

উপকারিতা: উচ্চতর থ্রুপুট, অবিচ্ছিন্ন গুণগত মান, ও কর্মী খরচে নাটকীয় সাশ্রয়।

২. স্বয়ংক্রিয়তার বিনিয়োগ ও মূল্য নির্ধারণ

স্বচ্ছ কস্ট টিয়ার–এর মাধ্যমে আপনার ROI পরিকল্পনা করুন:

| ফার্ম আকার | পাখির সংখ্যা | বিনিয়োগের পরিধি (USD) |

|---|---|---|

| ছোট-পরিসর | 2,000–10,000 | $100,000–$250,000 |

| মধ্য-পরিসর | 10,000–50,000 | $250,000–$600,000 |

| বৃহৎ কমপ্লেক্স | 50,000+ | $600,000–$1,000,000+ |

মূল্য নির্ধারণের প্রধান চালিকা শক্তি: কেজ টিয়ার, ক্লাইমেট কন্ট্রোল সিস্টেম, রোবোটিক ডিম-হ্যান্ডলিং, এবং স্টিল-স্ট্রাকচার ইন্টিগ্রেশন।

৩. সঠিক নির্মাতা নির্বাচন

সরবরাহকারী নির্ধারণের জন্য এই টপ ট্রেইট–গুলো খুঁজুন:

গবেষণা ও উদ্ভাবন

– উন্নত IoT প্ল্যাটফর্ম, প্রেডিক্টিভ ডেটা অ্যানালিটিক্স, এবং স্মার্ট সেন্সর।গঠনগত মান

– ক্ষয়-প্রতিরোধী মেটেরিয়াল, প্রিসিশন মেশিনিং, এবং মডুলার ডিজাইন।পর-বিক্রয় সেবা

– অন-সাইট কমিশনিং, অপারেটর প্রশিক্ষণ, রিমোট ডায়াগনস্টিক্স, এবং দ্রুত স্পেয়ার-পার্টস ডেলিভারি।

কেন Yunhua?

আমাদের প্রতিযোগিতামূলক মূল্য, ISO-সার্টিফাইড প্রোডাকশন, এবং ৫০+ দেশে প্রমাণিত গ্লোবাল ট্র্যাক রেকর্ড–এর সংমিশ্রণ আপনাকে সেরা নিশ্চিত করে।

৪. সরঞ্জামের বৈচিত্র্য ও বাজার চাহিদা

আজকের ফার্মগুলো যে কোন স্তরের অটোমেশন–ই বেছে নিতে পারে:

বেসিক খাঁচা লাইন

ম্যানুয়াল ফিডিং + সেমি-অটোমেটিক পানির ব্যবস্থামধ্য-স্তরের অটোমেশন

ইলেকট্রনিক ডিম গ্রেডিং + ক্লাইমেট-নিয়ন্ত্রিত ব্রুডারসম্পূর্ণ স্বয়ংক্রিয় ফ্যাক্টরি

ইনক্যুবে�শন, ফিডিং, গ্রেডিং, প্যাকিং, এবং টার্নকি স্টিল-স্ট্রাকচার বিল্ডিং

বাজার চালিকা শক্তি: বর্ধিত শ্রম খরচ, কঠোর বায়োসিকিউরিটি নিয়ম, এবং স্কেলেবল, মডুলার প্ল্যাটফর্ম–এর প্রয়োজন।

৫. সুবিধা ও বাস্তব চ্যালেঞ্জ

সুবিধা

৬০% পর্যন্ত শ্রম হ্রাস

৩০%+ উৎপাদনশীলতা বৃদ্ধি

স্বয়ংক্রিয় বর্জ্য ব্যবস্থাপনা–এর মাধ্যমে উন্নত সংগৃহীত স্বাস্থ্য

কন্টিনিউয়াস পরিবেশ নিয়ন্ত্রণ

চ্যালেঞ্জ

উচ্চ প্রারম্ভিক মূলধন

প্রশিক্ষিত টেকনিক্যাল স্টাফের প্রয়োজন

স্থানীয় সার্ভিস অবকাঠামোর পার্থক্য

প্রো টিপ: প্রমাণিত সিস্টেম ডিজাইন, সম্পূর্ণ প্রশিক্ষণ, এবং লোকাল সার্ভিস এগ্রিমেন্ট–এর মাধ্যমে ঝুঁকি স্বাভাবিক করুন।

৬. উদীয়মান প্রবণতা

এআই ও আইওটি একীকরণ: রিয়েল-টাইম স্বাস্থ্য মনিটরিং, প্রেডিক্টিভ মেইনটেন্যান্স, স্বয়ংক্রিয় ডিসিশন-মেকিং।

সবুজ কৃষি: সোলার-পাওয়ারড ভেন্টিলেশন, ফিড-সেভিং ট্রাফ, বর্জ্য-অনুবর্তক সার্কুলার লুপ।

মডুলার সম্প্রসারণ: নির্দিষ্ট ব্রীড ও দ্রুত স্কেলিং–এর জন্য কাস্টম মডিউল।

ওয়ান-স্টপ প্ল্যাটফর্ম: একক পার্টনার সলিউশন—ফার্ম ডিজাইন থেকে ডিজিটাল ম্যানেজমেন্ট পর্যন্ত।

উপসংহার ও আহ্বান

আধুনিক, বুদ্ধিমান পোল্ট্রি সরঞ্জাম মুরগি চাষে ভূমি ব্যবহারে সর্বোচ্চ, উৎপাদন বৃদ্ধি, এবং পশু কল্যাণ নিশ্চিত করছে। আপনি ১০,০০০ পাখি–র স্টার্টার ফার্ম বা ১০ লক্ষ পাখি–র কমপ্লেক্স পরিকল্পনা করুন—সঠিক অটোমেশন লেভেলই দেবে স্থিতিশীল লাভ।

আপনার অপারেশন রূপান্তর করতে প্রস্তুত?

আজই আমাদের সাথে ফ্রি পরামর্শ, কাস্টম ফার্ম ডিজাইন, এবং টার্নকি বাস্তবায়নের জন্য যোগাযোগ করুন!

পশুপালন সরঞ্জাম প্রস্তুতকারক: বিশ্বব্যাপী স্বয়ংক্রিয় পোল্ট্রি ফার্মিং চালনায় অগ্রণী

বুদ্ধিমান পশুপালন সিস্টেম–এর মাধ্যমে পোল্ট্রি উৎপাদন–এ রূপান্তর

Livestock Farming Equipment Co., Ltd. স্বয়ংক্রিয় পোল্ট্রি ফার্মিং–এর অগ্রদূত, টার্নকি সমাধান দিয়ে উৎপাদনশীলতা বৃদ্ধি, বায়োসিকিউরিটি উন্নত, ও ROI সর্বাধিক করে। দশকের ক্যাটকাটিং-এজ উৎপাদন সক্ষমতা ও বিশ^্বব্যাপী নমুনা বাস্তবায়ন–এর মাধ্যমে আমরা সেবা দিচ্ছি প্রাইভেট ব্যাকইয়ার্ড থেকে ১,০০০,০০০ পাখি–এর বাণিজ্যিক কমপ্লেক্স পর্যন্ত, এশিয়া, মধ্যপ্রাচ্য, আফ্রিকা, ও দক্ষিণ আমেরিকা জুড়ে।

১. কোম্পানি ওভারভিউ

প্রিসিশন পশুপালন সরঞ্জাম প্রস্তুতকারক হিসেবে আমাদের পূর্ণ-চক্র সেবা অন্তর্ভুক্ত:

কাস্টম ফার্ম ডিজাইন: সাইট-নির্দিষ্ট লেআউট ও ভূমিকম্প-প্রতিরোধী, বাতাস-প্রতিরোধী স্টিল-স্ট্রাকচার বার্ন।

ইন-হাউস প্রোডাকশন: ISO-9001 সার্টিফাইড খাঁচা সিস্টেম, ফিডার, ড্রিঙ্কার, ও পারিবেশিক নিয়ন্ত্রণ নির্মাণ।

গ্লোবাল ডিপ্লয়মেন্ট: ৫০টিরও বেশি দেশে পেশাদার ইনস্টলেশন ও অপারেটর প্রশিক্ষণ।

আজীবন সাপোর্ট: ২৪/৭ রিমোট ডায়াগনস্টিক্স, স্পেয়ার-পার্টস লজিস্টিকস, ও এলাকা ভিত্তিক ফিল্ড সার্ভিস।

২. উন্নত পোল্ট্রি খাঁচা সিস্টেম

আমাদের মাল্টি-টিয়ার লেয়ার ক্যেজ এবং ব্রয়লার মডিউল–এ রয়েছে:

সিঙ্গল ও মাল্টি-টিয়ার ডিজাইন: একাধিক স্তরে ভার্টিক্যাল স্ট্যাকিং ও ইন্টিগ্রেটেড ডিম কালেকশন কনভেয়র।

ব্রয়লার খাঁচা: উচ্চ-প্রবাহ ভেন্টিলেশন, ইনসুলেটেড ব্রুডার, ও স্বয়ংক্রিয় ফিডিং লাইন।

এর্গონომিক অ্যাক্সেস: সহজ পরিষ্কার, বর্জ্য অপসারণ, ও স্বাস্থ্য মনিটরিং এর মাধ্যমে উন্নত বায়োসিকিউরিটি।

৩. পূর্ণ-স্বয়ংক্রিয় পালন সমাধান

স্মার্ট ফার্মিং সরঞ্জাম দিয়ে প্রতিটি পালনের ধাপ স্বয়ংক্রিয় করুন:

প্রোগ্রামযোগ্য ফিডিং সিস্টেম: মন্তব্যে-কমানো বর্জ্য ও স্থিতিশীল বৃদ্ধি নিশ্চিত করে।

সেল্ফ-ক্লিনিং ওয়াটার লাইন: নির্দিষ্ট প্রবাহ ও তাপমাত্রা নিয়ন্ত্রণ, রোগ ঝুঁকি হ্রাস করে।

IoT-সক্ষম পরিবেশ নিয়ন্ত্রণ: রিয়েল-টাইম তাপমাত্রা, আর্দ্রতা, ও বায়ু-অদলবদল ম্যানেজ করে।

উচ্চ-গতি ডিম হ্যান্ডলিং: অপটিক্যাল সেন্সর ও নরম কনভেয়র–এর মাধ্যমে ব্রেকেজ ও শ্রম কমায়।

৪. বিনিয়োগ ও ROI বিশ্লেষণ

স্পষ্ট খরচ সীমা ও ROI চালক–এর মাধ্যমে আপনার আপগ্রেড পরিকল্পনা করুন:

| ফার্ম আকার | পাখির সংখ্যা | বিনিয়োগ (USD) |

|---|---|---|

| ছোট (≤10,000 পাখি) | ≤10,000 | $100K–200K |

| মাঝারি (10K–50K) | 10,000–50,000 | $200K–500K |

| বড় কমপ্লেক্স (50K+) | 50,000+ | $500K–1M+ |

ROI চালকসমূহ:

পরিশ্রম বাঁচানো (৬০% পর্যন্ত)

ফিড-রূপান্তর উন্নয়ন

স্থিতিশীল পণ্য গুণ

উন্নত পশু কল্যাণ

৫. উদীয়মান প্রবণতা

ভবিষ্যত ধরতে আমাদের দৃষ্টিভঙ্গি:

এআই & প্রেডিক্টিভ অ্যানালিটিক্স: পাল সুস্থতা মনিটরিং

নবায়নযোগ্য শক্তি একীকরণ: সোলার ভেন্টিলেশন ও বর্জ্য-সার্কুলার লুপ

মডুলার এক্সপ্যানশন কিট: দ্রুত স্কেলিং

ওয়ান-স্টপ ডিজিটাল প্ল্যাটফর্ম: ডিজাইন, সরঞ্জাম, ও ফার্ম ম্যানেজমেন্ট একত্রে

আপনার পোল্ট্রি অপারেশন রূপান্তর করতে প্রস্তুত?

আজই আমাদের গ্লোবাল টিম–এর সাথে ফ্রি পরামর্শ ও কাস্টম প্রস্তাবনা পান:

📱 WhatsApp: +86 139 1785 6548

📧 Email: yunhua@xiansh.cn

পশুপালন সরঞ্জাম প্রস্তুতকারক: বিশ্বব্যাপী স্বয়ংক্রিয় পোল্ট্রি ফার্মিং চালনায় অগ্রণী

পশুপালন সরঞ্জাম প্রস্তুতকারক: বিশ্বব্যাপী স্বয়ংক্রিয় পোল্ট্রি ফার্মিং চালনায় অগ্রণী

বুদ্ধিমান পশুপালন সিস্টেম–এর মাধ্যমে পোল্ট্রি উৎপাদন–এ রূপান্তর

Livestock Farming Equipment Co., Ltd. স্বয়ংক্রিয় পোল্ট্রি ফার্মিং–এর অগ্রদূত, টার্নকি সমাধান দিয়ে উৎপাদনশীলতা বৃদ্ধি, বায়োসিকিউরিটি উন্নত, ও ROI সর্বাধিক করে। দশকের ক্যাটকাটিং-এজ উৎপাদন সক্ষমতা ও বিশ^্বব্যাপী নমুনা বাস্তবায়ন–এর মাধ্যমে আমরা সেবা দিচ্ছি প্রাইভেট ব্যাকইয়ার্ড থেকে ১,০০০,০০০ পাখি–এর বাণিজ্যিক কমপ্লেক্স পর্যন্ত, এশিয়া, মধ্যপ্রাচ্য, আফ্রিকা, ও দক্ষিণ আমেরিকা জুড়ে।

১. কোম্পানি ওভারভিউ

প্রিসিশন পশুপালন সরঞ্জাম প্রস্তুতকারক হিসেবে আমাদের পূর্ণ-চক্র সেবা অন্তর্ভুক্ত:

কাস্টম ফার্ম ডিজাইন: সাইট-নির্দিষ্ট লেআউট ও ভূমিকম্প-প্রতিরোধী, বাতাস-প্রতিরোধী স্টিল-স্ট্রাকচার বার্ন।

ইন-হাউস প্রোডাকশন: ISO-9001 সার্টিফাইড খাঁচা সিস্টেম, ফিডার, ড্রিঙ্কার, ও পারিবেশিক নিয়ন্ত্রণ নির্মাণ।

গ্লোবাল ডিপ্লয়মেন্ট: ৫০টিরও বেশি দেশে পেশাদার ইনস্টলেশন ও অপারেটর প্রশিক্ষণ।

আজীবন সাপোর্ট: ২৪/৭ রিমোট ডায়াগনস্টিক্স, স্পেয়ার-পার্টস লজিস্টিকস, ও এলাকা ভিত্তিক ফিল্ড সার্ভিস।

২. উন্নত পোল্ট্রি খাঁচা সিস্টেম

আমাদের মাল্টি-টিয়ার লেয়ার ক্যেজ এবং ব্রয়লার মডিউল–এ রয়েছে:

সিঙ্গল ও মাল্টি-টিয়ার ডিজাইন: একাধিক স্তরে ভার্টিক্যাল স্ট্যাকিং ও ইন্টিগ্রেটেড ডিম কালেকশন কনভেয়র।

ব্রয়লার খাঁচা: উচ্চ-প্রবাহ ভেন্টিলেশন, ইনসুলেটেড ব্রুডার, ও স্বয়ংক্রিয় ফিডিং লাইন।

এর্গონომিক অ্যাক্সেস: সহজ পরিষ্কার, বর্জ্য অপসারণ, ও স্বাস্থ্য মনিটরিং এর মাধ্যমে উন্নত বায়োসিকিউরিটি।

৩. পূর্ণ-স্বয়ংক্রিয় পালন সমাধান

স্মার্ট ফার্মিং সরঞ্জাম দিয়ে প্রতিটি পালনের ধাপ স্বয়ংক্রিয় করুন:

প্রোগ্রামযোগ্য ফিডিং সিস্টেম: মন্তব্যে-কমানো বর্জ্য ও স্থিতিশীল বৃদ্ধি নিশ্চিত করে।

সেল্ফ-ক্লিনিং ওয়াটার লাইন: নির্দিষ্ট প্রবাহ ও তাপমাত্রা নিয়ন্ত্রণ, রোগ ঝুঁকি হ্রাস করে।

IoT-সক্ষম পরিবেশ নিয়ন্ত্রণ: রিয়েল-টাইম তাপমাত্রা, আর্দ্রতা, ও বায়ু-অদলবদল ম্যানেজ করে।

উচ্চ-গতি ডিম হ্যান্ডলিং: অপটিক্যাল সেন্সর ও নরম কনভেয়র–এর মাধ্যমে ব্রেকেজ ও শ্রম কমায়।

৪. বিনিয়োগ ও ROI বিশ্লেষণ

স্পষ্ট খরচ সীমা ও ROI চালক–এর মাধ্যমে আপনার আপগ্রেড পরিকল্পনা করুন:

| ফার্ম আকার | পাখির সংখ্যা | বিনিয়োগ (USD) |

|---|---|---|

| ছোট (≤10,000 পাখি) | ≤10,000 | $100K–200K |

| মাঝারি (10K–50K) | 10,000–50,000 | $200K–500K |

| বড় কমপ্লেক্স (50K+) | 50,000+ | $500K–1M+ |

ROI চালকসমূহ:

পরিশ্রম বাঁচানো (৬০% পর্যন্ত)

ফিড-রূপান্তর উন্নয়ন

স্থিতিশীল পণ্য গুণ

উন্নত পশু কল্যাণ

৫. উদীয়মান প্রবণতা

ভবিষ্যত ধরতে আমাদের দৃষ্টিভঙ্গি:

এআই & প্রেডিক্টিভ অ্যানালিটিক্স: পাল সুস্থতা মনিটরিং

নবায়নযোগ্য শক্তি একীকরণ: সোলার ভেন্টিলেশন ও বর্জ্য-সার্কুলার লুপ

মডুলার এক্সপ্যানশন কিট: দ্রুত স্কেলিং

ওয়ান-স্টপ ডিজিটাল প্ল্যাটফর্ম: ডিজাইন, সরঞ্জাম, ও ফার্ম ম্যানেজমেন্ট একত্রে

আপনার পোল্ট্রি অপারেশন রূপান্তর করতে প্রস্তুত?

আজই আমাদের গ্লোবাল টিম–এর সাথে ফ্রি পরামর্শ ও কাস্টম প্রস্তাবনা পান:

📱 WhatsApp: +86 139 1785 6548

📧 Email: yunhua@xiansh.cn

সরঞ্জাম ফিচারসমূহ

H-টাইপ স্ট্যাকড খাঁচা: স্থান সাশ্রয়ী, টেকসই, ভিন্ন ঘর বিন্যাসে উপযোগী

স্বয়ংক্রিয় খাবার ও মেডিকেটেড পানি: শ্রম কম, জনপ্রাণীর টিকে থাকা ও ডিম দেওয়া স্থিতিশীল

ডিম সংগ্রহ কনভেয়র: গ্রেডিং লাইনের সাথে সংযোগ, ভাঙ্গা ও হ্যান্ডলিং খরচ কমাতে