0

প্রবণতার অগ্রভাগে থাকা, ভবিষ্যতের অন্তর্দৃষ্টি

প্রবণতার অগ্রভাগে থাকা: ভবিষ্যতের অন্তর্দৃষ্টি

আজকের দ্রুত পরিবর্তনশীল বিজনেস ল্যান্ডস্কেপে, যারা আগামী দিনের প্রবণতা সঠিকভাবে পূর্বাভাস দিতে পারে, তারাই প্রতিযোগিতামূলক সুবিধা বজায় রাখতে সক্ষম। নতুন মার্কেট ডায়নামিকস বুঝতে এবং সাস্টেইনেবল গ্রোথ অর্জনে মূল চাবিকাঠি হলো ট্রেন্ড ইনটেলিজেন্স ও অ্যাজাইল রেসপন্স।

ট্রেন্ড ইনটেলিজেন্স: ডেটা দিয়ে ভবিষ্যতের সুযোগ তৈরি করুন

গভীর গবেষণা: বাজারের বিগ ডেটা, ইন্ডাস্ট্রি রিপোর্ট, এবং ইউজার বিহেভিয়ার অ্যানালাইসিস ব্যবহার করে নতুন ডিমান্ড ও প্রযুক্তিগত অগ্রগতি সনাক্ত করুন।

ফরওয়ার্ড ভিশন: নীতি পরিবর্তন, বিনিয়োগ প্রবাহ, এবং গ্লোবাল হটস্পট ট্র্যাক করে আপনার স্ট্র্যাটেজিক ভিউ বিস্তৃত করুন।

নিরবিচ্ছিন্ন পুনরাবৃত্তি: অ্যাজাইল টেস্ট-অ্যান্ড-লার্ন পদ্ধতি গ্রহণ করুন—ছোট পাইলট চালিয়ে রিয়েল-টাইম ফিডব্যাক অনুযায়ী দ্রুত ইনোভেশন পরিমার্জন করুন।

কেস স্টাডি: একটি ম্যানুফ্যাকচারিং প্রতিষ্ঠান আইওটি ডেটা মনিটরিং কাজে লাগিয়ে ডাউনটাইম ৩০% কমিয়েছিল। এর ফলে কস্ট রিডাকশন ও ইফিসিয়েন্সি বুস্ট হয় এবং স্মার্ট ম্যানুফ্যাকচারিং–এ নতুন মাইলস্টোন স্থাপন হয়।

অ্যাজাইল রেসপন্স: আপনার “ফিউচার-রেডি” টিম গড়ে তুলুন

মড্যুলার আর্কিটেকচার: পণ্য ও সেবাকে প্লাগ-অ্যান্ড-প্লে মডিউল হিসেবে ডিজাইন করুন, যাতে বাজারের শিফট এর সাথে স্কেল ও অ্যাডাপ্ট করা যায়।

ক্রস-ফাংশনাল টিম: ডেটা সায়েন্স, মার্কেটিং, R&D, এবং সাপ্লাই চেইন বিশেষজ্ঞদের একত্রিত করে ইনোভেশন সাইকেল ত্বরান্বিত করুন।

রিস্ক ম্যানেজমেন্ট: মাল্টি-লেয়ারড ইয়ার্লি-ওয়ার্নিং সিস্টেম গড়ে তুলুন, যাতে সাপ্লাই চেইন ডিস্রাপশন, রেগুলেটরি চেঞ্জ, বা কম্পিটি টিভ মুভ দ্রুত শনাক্ত ও সমাধান করা যায়।

সেরা অনুশীলন: কোয়ার্টারলি অ্যাজাইল স্প্রিন্ট নিয়ে নতুন ফিচার বা মার্কেট পাইলট করুন, প্রতিটি ইটারেশন–এ মেজারেবল ভ্যালু নিশ্চিত করুন।

ভবিষ্যতের নেতৃত্ব: ইন্টেলিজেন্স, ইকোসিস্টেম, সাস্টেইনেবিলিটি

এআই ও অটোমেশন: মেশিন লার্নিং ও অটোমেটেড ওয়ার্কফ্লো–এর মাধ্যমে ডিসিশন মেকিং সুপারচার্জ করুন, কর্মীকে উচ্চ-মুল্য কাজ–এ মুক্ত রাখুন এবং কোর ইনোভেশন ত্বরান্বিত করুন।

ইকোসিস্টেম কলাবোরেশন: আপনার কোর অফারিং–এর চারপাশে ওপেন প্ল্যাটফর্ম তৈরি করে আপস্ট্রিম সাপ্লায়ার, ডাউনস্ট্রিম কাস্টমার, এবং ইনোভেটিভ স্টার্টআপ–দের সাথে কো-ক্রিয়েশন করুন।

গ্রিন ইনোভেশন: লো-কার্বন প্রোডাকশন ও সার্কুলার ইকোনমি মডেল গ্রহণ করে রেগুলেশন মেনে চলুন এবং কনজিউমার ট্রাস্ট জিতে নিন।

ভবিষ্যৎ প্রত্যাশা: ডিজিটাল ট্রান্সফরমেশন ও গ্রিন টেকনোলজি–এর যুগল ইঞ্জিনে আপনি ইন্ডাস্ট্রি আপগ্রেড করবেন এবং নতুন মার্কেট আপোর্চুনিটি দখল করবেন।

এখনই পদক্ষেপ নিন, আগামীর স্বাগতম জানান

ভবিষ্যত অপেক্ষা করবে না—অ্যাপচুনিটি তৈরী হয় প্রস্তুত থাকলে। আমাদের সাথে ইন্টেলিজেন্ট ইনসাইট ও অ্যাজাইল এক্সিকিউশন–এর জন্য অংশীদার হোন, প্রথম-পদক্ষেপের সুবিধা নিন এবং সাস্টেইনেবল গ্রোথ অর্জন করুন।

👉 ফ্রি হোয়াইট পেপার “ভবিষ্যত অন্তর্দৃষ্টি ও স্ট্র্যাটেজিক প্ল্যানিং” পেতে এখনই যোগাযোগ করুন।

ডিম গ্রেডিং মেশিনের অংশগুলো কী, কোন যন্ত্রাংশ নিয়ে গঠিত, আপনি কি জানেন?

ডিম গ্রেডিং মেশিনের উপাদান ও সরঞ্জাম

আপনি কি জানেন ডিম গ্রেডিং মেশিন কোন কোন কম্পোনেন্ট ও সরঞ্জাম দিয়ে গঠিত?

আপনার পোল্ট্রি খামার কি ডিম কনভেয়র বেল্ট অথবা ডিম কালেক্টর এর মাধ্যমে সরাসরি আমাদের গ্রেডিং মেশিন-এ ডিম সরবরাহ করে?

যদি না—অর্থাৎ ডিম কালেক্টর দিয়ে সরাসরি না সংযুক্ত—তাহলে কি আপনাদের অটোমেটেড ডিম-লোডিং সিস্টেম প্রয়োজন?

আপনার খামার প্রতিদিন কতটি ডিম تولید করে, এবং দৈনিক কতটি ডিম গ্রেডিং করতে হয়?

সম্ভাব্য মডিউল সমূহ

আপনার খামারের সেটআপ ও চাহিদা অনুযায়ী একটি সম্পূর্ণ গ্রেডিং লাইন নিম্নলিখিত মডিউলগুলির যেকোনো কম্বিনেশনে গঠিত হতে পারে:

ডিম কালেক্টর ইন্টারফেস বা অটোমেটেড ডিম লোডার

ডিম এয়ার-ব্লো ক্লিনিং ইউনিট বা ডিম ওয়াশিং ইউনিট

ডিম ড্রায়িং ইউনিট

ডিম অপটিক্যাল ইনস্পেকশন ইউনিট

ডিম আল্ট্রাভায়োলেট স্টেরিলাইজেশন ইউনিট

ডিম অয়ালিং ইউনিট

ইন্টেলিজেন্ট ডিম-ক্র্যাক ডিটেকশন ইউনিট

ময়লা ও ভাঙ্গা ডিম শনাক্তকরণ ইউনিট

ডিম ওজন ও গ্রেডিং ইউনিট (পাঁচটি ওজন শ্রেণি)

অটোমেটিক ডিম-ট্রে লোডিং ইউনিট

অটোমেটিক ডিম-কোডিং ও প্রিন্টিং ইউনিট

আপনার প্রয়োজনীয়তা জানান

আপনার বিস্তারিত চাহিদা (গ্রেডিং মেশিনের স্পেসিফিকেশন ও দৈনিক গ্রেডিং ক্যাপাসিটি) আমাদের জানান,

আমরা কাস্টমাইজড সলিউশন ডিজাইন করে প্রতিযোগিতামূলক কোটেশন প্রদান করব।

যোগাযোগ ও আরও তথ্য

WhatsApp: +86 139 1785 6548

ওয়েবসাইট: https://www.bn.xiansh.cn/

আমরা দশটি ভাষায় পেশাদার প্রোডাক্ট সাইট পরিচালনা করি—আপনার পছন্দের ভাষায় সাইট পরিদর্শন করে বিস্তারিত জানুন!

আপনি কি স্বয়ংক্রিয় বুদ্ধিমান ডিম গ্রেডিং মেশিনের সম্পূর্ণ নির্দেশ প্রবাহ জানেন?

সম্পূর্ণ অপারেটিং ফ্লো: স্বয়ংক্রিয় ও ইন্টেলিজেন্ট ডিম গ্রেডিং মেশিন

ধাপ 1: ডিম লোডিং সিস্টেম

আপনার পোল্ট্রি ফার্ম–এর ডিম কালেকশন সিস্টেম (কেজের সেন্ট্রাল ডিম কনভেয়িং বেল্ট বা অটোমেটিক সাকশন-কাপ লোডার) দ্বারা ডিম সরাসরি গ্রেডিং মেশিন–এ প্রদান করা হয়।

দু-স্তরের মডুলার কনভেয়র বেল্ট–এ বিল্ট-ইন সেন্সর রয়েছে, যা ডিম জ্যাম সনাক্ত করে এবং ফিড স্পিড স্বয়ংক্রিয়ভাবে সামঞ্জস্য করে।

দ্বিতীয় স্তরে সুইং লেন ডিভাইস ডিমগুলো সমানভাবে পৃথক ট্র্যাকে বিতরণ করে, যাতে অপটিকাল ইনস্পেকশন ইউনিট–এ স্থানান্তর মসৃণ ও বিন্যস্ত হয়।

ধাপ 2: অটোমেটেড LED অপটিক্যাল ইনস্পেকশন

ডিমগুলো কনভেয়র দিয়ে LED ইনস্পেকশন চেম্বার–এ প্রবেশ করে, যেখানে ছয়টি সারি রোলার-মাউন্টেড LEDs মাউন্ট করা আছে।

প্রতিটি ডিম মাল্টি-ওয়েভলেংথ LED আলোর নিচে ঘুরিয়ে ক্র্যাক, রক্তের দাগ, আকারের ত্রুটি এবং তারতাজা অবস্থা মূল্যায়ন করা হয়।

শুধুমাত্র শীর্ষ-মানের ডিমই পরবর্তী ধাপে যাওয়ার অনুমোদন পায়।

ধাপ 3: অটোমেটেড ডিম ধোয়া

LED ইনস্পেকশনের পর ডিমগুলো রোটেটিং ব্রাশ রোলার সমৃদ্ধ ওয়াশ সিস্টেম–এ প্রবেশ করে:

স্বতন্ত্র রোলার ড্রাইভ: প্রতিটি ডিমকে আলাদা ঘোরিয়ে ইউনিফর্ম ব্রাশিং নিশ্চিত করে।

সিল-লার্প লুপ ওয়াটার রিসার্কুলেশন: হট ও অ্যাম্বিয়েন্ট ওয়াটার এবং ক্লিনিং এজেন্ট (ইনজেকশন পোর্ট) নিখুঁতভাবে মাপজোক করে, জল ও শক্তি খরচ কমায়।

তিন-স্টেজ ধোয়া:

ব্রাশসহ রিসার্কুলেটেড ওয়াটার ওয়াশ

তাজা পানি রিন্স

ডিসইনফেক্ট্যান্ট মিস্ট স্প্রে

ধাপ 4: অটোমেটেড ডিম শুকানো

ধোয়ার পর ডিমগুলো ড্রায়িং কনভেয়র–এ যায়, যেখানে আছে:

ওয়েট/ড্রাই জোন সেপারেশন: আলাদা ড্রাইভ সিস্টেম–এর মাধ্যমে আর্দ্রতা স্থানান্তর রোধ।

অ্যাসরবেন্ট রোলার সিস্টেম অতিরিক্ত পানি শোষণ করে।

জেন্টল লো–টেম্পারেচার এয়ার ব্লো: “মিডল, স্মল এন্ড, বিগ এন্ড”–এর সব দিক শুকাতে বলো-নোজল ব্যবহার করে, রোলার রোটেশন সম্পূর্ণ শুষ্কতা নিশ্চিত করে।

ধাপ 5: অটোমেটেড অয়েল কোটিং (অ্যাটোমাইজড)

শুকনো ডিমগুলো ফুড-গ্রেড মিনারেল অয়েল–এর ফাইন মিস্ট–এ ঢেলে রোটেটিং রোলার–এর মাধ্যমে প্রতিরক্ষামূলক ফিল্ম তৈরি করে:

অ্যাডজাস্টেবল অয়েল মিস্ট ভলিউম কন্ট্রোল ও রিকভারি সিস্টেম।

কন্টিনিউয়াস রোটেশন নিশ্চিত করে ইভেন অয়েল কোভারেজ।

ধাপ 6: অটোমেটেড ওজন নেয়া ও গ্রেডিং

অয়েল কৃত ডিমগুলো ওজন পরিমাপ সিস্টেম–এ যায়, যেখানে PLC:

গ্রেড অনুসারে গণনা রেকর্ড করে।

মেশিন ইফিসিয়েন্সি টার্গেট ও প্রসেস প্যারামিটার সেট করার সুবিধা।

রিয়েল-টাইম মনিটরিং।

কী স্পেস:সঠিকতা: ±0.1 গ্রাম

ওভারহেড লোড সেল: ডিমের উপর থেকে ওজন নেওয়ার মাধ্যমে কন্টামিনেশন মুক্ত সঠিকতা।

জেন্টল গ্রিপার ডিজাইন: সফট “ডিম ক্ল ফ” মেকানিজম ডিম ক্ষতি রোধ করে।

ধাপ 7: অটোমেটেড ট্রে লোডিং ও প্যাকেজিং

গ্রেডিং শেষ ডিমগুলো ট্রে-লোডার–এ প্রবেশ করে:

ভার্টিকাল (কেবিনেট-স্টাইল) লোডার: ছোট ফার্ম–এর জন্য কম্প্যাক্ট, কস্ট-ইফেক্টিভ, এবং ইজি টু অপারেট, ৫×৬ (৩০ ডিম) বা ৬×৬ (৩৬ ডিম) ট্রে সমর্থন করে।

হরিজন্টাল হাই-ক্যাপাসিটি লোডার: বড় অপারেশন–এর জন্য ফাস্ট চেঞ্জওভার, ২×৫ (১০ ডিম) থেকে ৫×৬ (৩০ ডিম) ট্রে ফরম্যাট সমর্থন করে।

প্রতিটি প্যাকেজিং লেনে বড় এন্ড আপ, স্মল এন্ড ডাউন অটোমেটিক ডিম অরিয়েন্টেশন।

লেন স্পেসিং, হাইট, ও উইথ স্বতন্ত্রভাবে অ্যাডজাস্ট করা যায়—মেশিন বন্ধ না করেই।

সিঙ্গেল-লেন মেইনটেনেন্স–এ সব লাইন চলতে থাকে।

এই সাম্প্রতিক সম্পূর্ণ অপারেটিং প্রসিডিউর–এর মাধ্যমে আপনার ডিমগুলো গ্রেড, পরিদর্শন, ধোয়া, শুকানো, অয়েলিং, ওজনায়ন, ও প্যাকেজিং সমন্বয়ে বাজারের জন্য প্রস্তুত হয়।

👉 বিস্তারিত স্পেসিফিকেশন ও পার্সোনালাইজড কোটেশন পেতে WhatsApp এ যোগ করুন: +86 139 1785 6548

🌐 ওয়েবসাইট: https://www.bn.xiansh.cn/

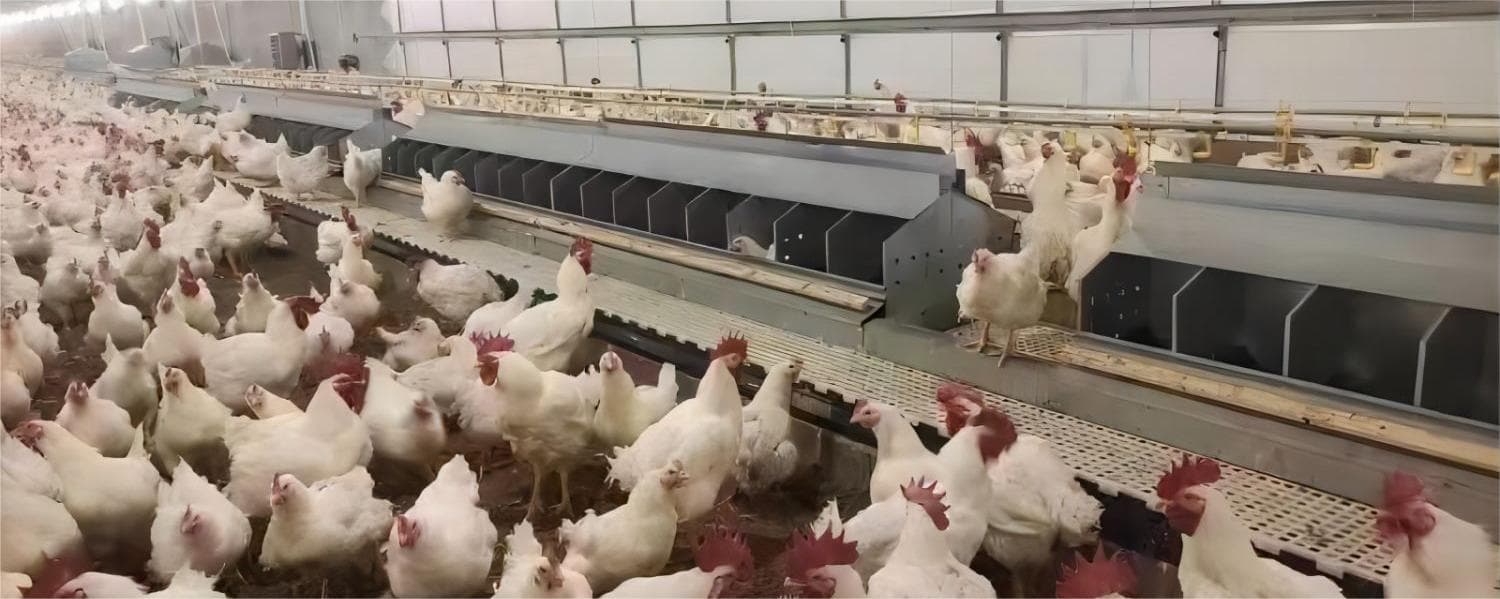

আপনি কি জানেন বায়ুরোধী মুরগি খাঁচা ফার্মিং সরঞ্জামের সুবিধাগুলি?

বায়ুনিরোধী মুরগি খাঁচা সরঞ্জামের সুবিধাসমূহ

নির্দিষ্ট পরিবেশ নিয়ন্ত্রণ

সম্পূর্ণ অবদ্ধ মুরগি গৃহ আপনাকে তাপমাত্রা, আর্দ্রতা, বায়ুচলাচল, এবং আলোন্ত্রণ–এ দক্ষ নিয়ন্ত্রণ প্রদান করে। এর ফলে লেয়ার এবং ব্রয়লার উভয়েরই স্বাস্থ্য এবং উৎপাদনশীলতা বৃদ্ধি পায়। খোলা খামারের মতো বাহ্যিক আবহাওয়ার অপ্রত্যাশিত প্রভাব এড়িয়ে চলে, তাই উৎপাদন স্থিতিশীল এবং নির্দেশ্যনির্ভর হয়। ম্যানুয়াল এবং স্বয়ংক্রিয় নিয়ন্ত্রণ ব্যবস্থা ব্যবহার করে আপনি বৃদ্ধি হার, যৌন পরিপক্কতার সময়, এবং স্তন উত্পাদন চক্র (যেমন ফিড-রেস্ট্রিকশন বা ফোর্সড মোল্টিং) সুনির্দিষ্টভাবে ম্যানেজ করতে পারেন।

স্কেলেবল, ইন্টেন্সিভ প্রোডাকশন

অবদ্ধ-হাউস খাঁচা সিস্টেম–এ বড় পরিসরে এবং ইন্টেন্সিভ ফার্মিং সম্পাদন করা সম্ভব। ১,০০,০০০+ পাখি ধারণে সক্ষম সুবিন্যস্ত ফ্যাসিলিটি নির্মাণের মাধ্যমে ফ্লোর স্পেস–এর সর্বোত্তম স্টকিং ডেনসিটি এবং ল্যান্ড-ইউজ এফিসিয়েন্সি অর্জন করা যায়। স্ট্রিক্ট হ্যান্ডশিপ স্ট্যান্ডার্ড অনুসারে আপনার পাল বৃদ্ধি ও পারফরম্যান্স কন্ট্রোল করা যায়, এবং উতপাদিত ডিম ও মাংস সবসময় ন্যাশনাল কোয়ালিটি রেগুলেশন পূরণ বা ছাড়িয়ে যায়।

স্বয়ংক্রিয় ফিডিং, পানির ব্যবস্থা, ভেন্টিলেশন, লাইটিং, এবং ক্লাইমেট কন্ট্রোল–এর মাধ্যমে লেবার খরচ এবং ফিড ওয়েস্ট কমে, অপারেশনাল ইফিসিয়েন্সি বাড়ে এবং মোট উৎপাদন খরচ কাটে।

পেশাদার নির্মাতা ও আজীবন সাপোর্ট

আমরা ** poultry– এবং livestock–রিয়ারিং সরঞ্জাম**–এর বিশেষজ্ঞ নির্মাতা, যার “Automatic Farming Machinery” সিরিজ বিশ্বজুড়ে বিক্রি হয়। সব খাঁচা ফ্রেম নির্মিত Grade Q235 স্টিল থেকে, যা দীর্ঘমেয়াদি টেকসইতা নিশ্চিত করে। প্রতিটি পণ্যের জন্য আমরা আজীবন মেইনটেন্যান্স গ্যারান্টি প্রদান করি।

ব্যাপক পণ্য পরিসর ও কাস্টমাইজেশন

আমাদের প্রধান প্রোডাক্ট লাইন–গুলো অন্তর্ভুক্ত:

লেয়ার খাঁচা, রোস্টার খাঁচা, ব্রডিং খাঁচা, খরগোশ খাঁচা, পায়জেন খাঁচা ইত্যাদি

ফিড ট্রাফ, ম্যানিওর কালেকশন বোর্ড, স্বয়ংক্রিয় পানির ব্যবস্থা, ম্যানিওর ক্লিনার, অটোমেটিক ফিডার

হট-এয়ার ব্রুডার, ভেন্টিলেশন ফ্যান, ওয়েট-কাটনিং কুলিং প্যানেল ইত্যাদি

আমরা কাস্টম ডিজাইন ও ফ্যাব্রিকেশন–এও পারদর্শী, গ্রাহক-নির্দিষ্ট মাত্রা বা পারফরম্যান্স–এর যে কোনো চাহিদা পূরণ করে থাকি।

👉 কোনো প্রশ্ন থাকলে ফ্রি প্রোডাক্ট ব্রোশিওর ও ডিটেইলড ইনফরমেশন পেতে এখনই কল করুন!

আপনি কি জানেন ল্যামিনেটেড মুরগি খাঁচা সরঞ্জামের সামগ্রিক ফিডিং অপারেশন নীতি?

H-টাইপ স্তরভিত্তিক মুরগি খাঁচা সিস্টেমের সার্বিক অপারেশন নীতি

ফিড সাপ্লাই সিস্টেম

ফিড ডেলিভারি: ফিড মিল থেকে ফিড ট্যanker–এ লোড করে অন-সাইট সাইলোগুলিতে পরিবহন।

কন্ট্রোলার: এক বা দুইটি সাইলো–র সাথে সংযোগ করে ফিড ডিসপেন্সিং চালু/বন্ধ করে এবং সমস্ত ফিডিং ডেটা লগ করে।

ফিড কার: কনভেয়র ও ডিস্ট্রিবিউশন মেকানিজম–এর মাধ্যমে ফিড গ্রহণ করে, তারপর লেভেলিং ডিভাইসের সাহায্যে সমানভাবে ট্রাফ–এ জমা দিতেই সামনে- পিছনে যান।

উচ্চতা ও ফ্লো অ্যাডজাস্টমেন্ট: ইনলেট রেগুলেটর–এ ফিড ড্রপ উচ্চতা সেট করে ফ্লো রেট ও ইউনিফর্মিটি নিয়ন্ত্রণ। ট্রাফের শেষের কালেক্টর–গুলি পাশের যেকোনো স্পিলেজ ধরে ফিডের অপচয় রোধ করে।

সেল্ফ-প্রোপেল্ড ট্রান্সপোর্টার: সরাসরি ফিড থিকনেস অ্যাডজাস্ট করার ম্যানুয়াল টগল, এবং ওয়্যার-রেজিস্ট্যান্ট গাইড হুইল–এর মাধ্যমে ট্রাফের ঘর্ষণ কমিয়ে আয়ু বাড়ায়।

রেল-মাউন্টেড ফিড বেল্ট: ধারাবাহিক ডেলিভারি নিশ্চিত করতে প্রোপাইটারি ফিডার হেড, এবং অ্যাডজাস্টেবল হপার যাতে পাখির বয়স অনুসারে বড়ানো যায়। হট-ডিপ গ্যালভানাইজড ট্রাফ–এ স্লাইডিং ব্যাফল ও এন্টি-এস্কেপ ওয়্যার মাউন্ট আছে, যাতে পাখিরা নিরাপদে ও সহজে খাওয়াতে পারে।

পানিল ও চিকিৎসা সিস্টেম

ইন্টেলিজেন্ট ওয়াটার ম্যানেজমেন্ট: প্রতিটি ঘরে স্মার্ট ওয়াটার মিটার, ফিল্ট্রেশন-মিটারিং পাম্প, এবং ডোজিং ট্যাঙ্ক।

ব্যাক-ফ্লাশ ভালভ: ফ্লো রেট স্বয়ংক্রিয়ভাবে অ্যাডজাস্ট করে পাখির চাহিদা অনুযায়ী, এবং প্রয়োজনে পাইপিং পরিষ্কার করে।

অ্যাডজাস্টেবল ড্রিঙ্কার: দুইটি হাইট-অ্যাডজাস্টেবল ড্রিঙ্কিং লাইন, সব বয়সের পাখির জন্য উপযোগী।

ট্রান্সপারেন্ট প্রেশার টিউবিング: একনজরে ওয়াটার লেভেল ও প্রেশার পর্যবেক্ষণ।

ক্লাইমেট ইনভায়রনমেন্ট: সিলড হাউসে অটোমেটেড ওয়েট-কার্টেন কুলিং ও নেগেটিভ-প্রেশার ভেন্টিলেশন।

সিস্টেম স্যুইট: মাল্টি-টিয়ার স্ট্যাকড খাঁচা সলিউশন, যার মধ্যে আছে খাঁচা মডিউল, পানিল ও ডোজিং সিস্টেম, ম্যানিওর রিমুভাল, ডিম কালেকশন, ফিড সাপ্লাই, লাইটিং, সেন্ট্রাল কন্ট্রোল, এবং অডিও-ভিজ্যুয়াল অ্যালার্ম।

ডিম সংগ্রহ সিস্টেম

ইলাস্টিক স্লেন্টেড ফ্লোর: ৮° ঢালু পেরফোরেটেড মেশ–এ ডিম নরমভাবে ঢালিয়ে নিচে চলে যায়, ব্রেকেজ রেট হ্রাস করে।

সাইড গ্যাপ: প্রতিটি খাঁচার পাশে ১০ সেমি ফাঁকা করে এয়ার সাটারকিকলেশন বাড়ায় এবং বেল্ট ভেন্ট–থেকে প্রবেশ করা শীতল বাতাস ঘরে প্রবাহিত করে।

কনভেয়েন্স পাথ: খাঁচার ফ্লোর থেকে ডিম রড-স্টাইল কনভেয়র–এ চলে আসে, তারপর এলিভেটর বা সেন্ট্রাল এগ্রিকালচার পাইপলাইন–এ প্রবেশ করে।

হাই-প্রিসিশন কাউন্টার: ইনফ্রারেড লেজার সেন্সর ও বিল্ট-ইন ডিসপ্লে ডিম গননা রিয়েল-টাইমে দেখায়।

জেন্টল হ্যান্ডলিং: ডিম ঢালু কলেকটিং বেল্ট–এ নেমে, সেন্ট্রাল ট্রান্সপোর্ট বেল্ট–এ চলে যায় এবং ট্রান্সফারের সময় স্থির থাকে, ফলে ড্যামেজ প্রায় শূন্য।

ম্যানিওর রিমুভাল সিস্টেম

টিয়ার্ড কনভেয়র বেল্ট: প্রতিটি লেভেলের ম্যানিওর বেল্টে পড়ে, ঘর থেকে বাহিরে বহন করে এক্সটার্নাল কনভেয়র–তে, তারপর ট্রাকে লোড— সম্পূর্ণ খামারের হাইজিন নিশ্চিত করে।

রোবাস্ট বেল্ট ডিজাইন: ইউনিক ক্লিনিং বেল্ট ২ মি/মিনে চলে, মিসএলাইনমেন্ট বা এজ রোলওভার আটকায়। রিয়ার-এন্ড স্ট্রাকচার গ্রিন-ক্লিন নীতিতে অনুসৃত, অপারেশনের সময় ঘর পরিবেশে বিক্ষোভ কমায়।

পরিবেশ নিয়ন্ত্রণ সিস্টেম

স্মার্ট ক্লাইমেট ম্যানেজমেন্ট: ফুলি অটোমেটিক টেম্পারেচার-এন্ড-হিউমিডিটি সিস্টেম, রিয়েল-টাইম সেন্সর–এর মাধ্যমে পাখির ক্লাইমেট কমফোর্ট মনিটর করে।

ওয়েট-কার্টেন ও নেগেটিভ-প্রেশার ভেন্টিলেশন: ইন্টেলিজেন্ট ফ্যান–গুলি প্রয়োজনমতো চালু/বন্ধ হয়, রান-টাইম লগ–এর মাধ্যমে মেইনটেন্যন্স প্ল্যানিং সহজ হয়।

ইন্টিগ্রেটেড কন্ট্রোল: টাচ-স্ক্রিন বা PC/মোবাইল অ্যাপ–এর মাধ্যমে একাধিক ঘর নিয়ন্ত্রণ—

ফ্যান & কুলিং প্যাড

এয়ার-ফ্লো ডিফ্লেক্টর & ইনলেট

টেম্পারেচার, আর্দ্রতা, CO₂, নেগেটিভ-প্রেশার সেন্সর

মিনিমাম, টানেল, ল longitudinal ভেন্টিলেশন মোড

ক্লাউড কানেক্টিভিটি: আমাদের ফার্ম-ম্যানেজমেন্ট প্ল্যাটফর্ম প্রতিটি ঘরকে ইন্টারনেটের সাথে সংযুক্ত করে—যেকোনো স্থান থেকে অপারেশন মনিটরিং সম্ভব।

স্টিল-ফ্রেম পোল্ট্রি বার্ন–এর নির্মাণ থেকে H-টাইপ স্ট্যাকড খাঁচা মডিউল–এর ইনস্টল পর্যন্ত, আমরা টার্নকি ইঞ্জিনিয়ারিং, সাপ্লাই, এবং কমিশনিং–এর সম্পূর্ণ সেবা প্রদান করি।

👉 WhatsApp: +86 139 1785 6548 (বিস্তারিত তথ্য ও কাস্টমাইজড সলিউশন পেতে)